Backflow/Cross Connection Control Information

What causes backflow incidents to occur?

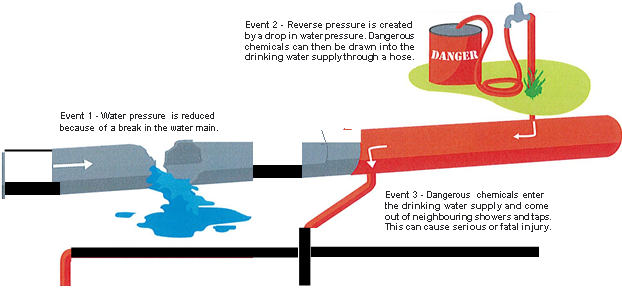

Backflow incidents are caused by either backpressure or backsiphonage.

- Backpressure is created when the pressure within the customer's system becomes greater than the water supply pressure. Elevated tanks, heating systems and booster pumps are some of the main causes of backpressure.

- Backsiphonage is created when there is a negative or reduced pressure in the water supply main. Water main breaks or hydrant flushing are two of the main causes of backsiphonage.

Can anyone test a backflow assembly?

No!!! Backflow assemblies must be tested by qualified individuals who have obtained the proper certifications pertaining to cross-connection and backflow assembly testing procedures. Each state (or possibly the local jurisdiction) establishes their own criteria and procedures for issuing certifications. Along with the state

issued certifications, several industry trade associations (USCFHRR, ASSE, TREEO, ABPA, GAWP, GWWI) offer training courses and certifications in the proper techniques for testing backflow prevention assemblies.

Who has responsibility for an approved and effective cross-connection control program?

The water purveyor, local plumbing authority, water customers and all individuals performing backflow prevention assembly installation, testing and repairs have some level of responsibility for ensuring an effective cross-connection control program. The cross-connection control program for each municipality must abide by the following per EPA guidelines.

- Develop an approved ordinance to govern the program in accordance with state cross-connection guidelines or regulations.

- On-site facility surveys to make the proper determination of hazard and method of protection required.

- Document and maintain all records pertaining to the field

- Maintain an accurate inventory of all backflow assemblies, and in some jurisdictions, backflow

- Developing a testing schedule of all testable backflow

- Notifying the water customer when assemblies are due for testing.

- Retain all assembly test

- Non-compliance enforcement action.

The water customer is responsible for preventing unprotected cross-connections and maintaining protected cross-connections within the water customer's facility. This should include the following:

<> Maintaining backflow devices ensuring cross-connections do not pose a risk to the water distribution system.

o Ensuring backflow assemblies are tested and maintained according to the testing schedule of the water purveyor by hiring qualified personnel in accordance with the local jurisdiction's criteria.

The backflow testers performing backflow prevention assembly installation, testing and repairs are responsible for following all codes and regulations as outlined by the local cross-connection control program. This should include the following:

- Holding all necessary and required credentials to properly install, test and maintain backflow

- Ensuring backflow assembly testing equipment is calibrated and working

- Testing the backflow assemblies in accordance with the proper testing

- Repairing backflow assemblies in accordance with manufacturer's authorized repair

- Properly identifying and documenting all backflow assembly information such as hazard, size, make, model, serial number, location, etc.

- Documenting the results of the backflow assembly

- Submitting test reports to the water purveyor within the required time frame.

- Provide to the water consumer a copy of the test results for their records.

CITY OF FAIRBURN GOVERNMENT-BACKFLOW TESTER DATABASE

This list is provided as a public service and is not an endorsement of any company.

The City of Fairburn Water Department does not attest to the capabilities of the below listed companies.

The State of Georgia requires that any repairs made to a backflow prevention assembly must be performed by a licensed plumber. All backflow prevention assemblies must be tested by a certified tester: (a) upon installation, (b) after any repairs are made to the assembly, and (c) annually thereafter. To be added to this list, contact Willie Smith at (404) 964-224, Ext. 121.

| COMPANY | PHONE NUMBER | TEST | REPAIR | INSTALLATIONS |

| AAA America Backflow Testing | (770) 218-0061 | X | ||

| Ability Backflow Testing & Installation | (770) 985-3717 | X | X | X |

| Able Inspection | (404) 277-1618 | X | X | X |

| Affirm Backflow, LLC | (678) 993-4812 | X | ||

| Alan Foster Plumbing, Inc. | (770) 929-0930 | X | X | X |

| Alliance Fire Protection Services, Inc. | (770) 554-5004 | X | X | X |

| Art Plumbing Co. | (770) 433-3232 | X | X | X |

| Backflow & Plumbing Solutions | (770) 652-3802 | X | X | X |

| Backflow Testing & Installation, LLC | (770) 918-1203 | X | X | X |

| Barnett Plumbing & Heating, Inc. | (770) 428-1044 | X | X | X |

| Central Fire Protection, Inc. | (770) 922-4250 | X | X | X |

| Century Fire Protection | (770) 945-2330 | X | ||

| Creative Multi-Care, Inc. | (770) 478-8728 | X | X | X |

| Delta Plumbing, Inc. | (770) 474-5555 | X | X | X |

| Fireaway, LLC | (770) 918-0527 | X | ||

| Fitzgerald & Sons Plumbing Company | (770) 487-8714 | X | X | X |

| FlowChek Backflow Preventer Testing Service | (770) 461-4083 | X | ||

| Head's Plumbing Sales & Service, Inc. | (404) 696-3175 | X | X | X |

| Houston Armour Backflow | (770) 285-4333 | X | ||

| International Fire Protection, Inc. | (770) 745-4530 | X | X | X |

| Marquise Commercial Plumbing, Inc. | (678) 546-7596 | X | X | X |

| Pepper's Backflow Services | (678) 300-8960 | X | ||

| Roberts Fire Protection | (678) 842-0202 | X | X | X |

| Wiginton Fire Systems | (678) 263-6513 | X | X | X |